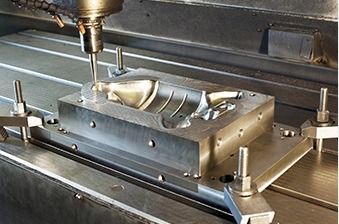

With the various manufacturing methods available today and a wide range of benefits they offer, businesses are looking for the best method they can use to produce their products in the fastest and most convenient way possible. This is the reason rapid tooling has become one of the most popular manufacturing methods for businesses nowadays, as it offers businesses the fast manufacturing method for prototypes, molds, and products with lower overall production costs.

Rapid tooling allows you to create different molds, prototypes, or tools simultaneously, which you can use for various purposes, such as product testing, production of final products, preparations for further manufacturing processes, and so on. This manufacturing method offers various benefits not available in other similar methods, such as rapid prototyping.

So, what are the benefits of rapid tooling? Here are the benefits of rapid tooling in manufacturing:

1. Making Multiple Molds Fast

Rapid tooling is the manufacturing process you can perform to create multiple molds at the same time, allowing you to make multiple molds fast. You can then use these molds to build various plastic products using the plastic molding or injection molding methods. So, you can create molds for multiple products or prototypes with rapid tooling, allowing you to save time and money in your manufacturing production and get your projects done faster.

With rapid tooling, you can also create multiple test products at a faster pace, allowing you to speed up your production, so that you can market your products faster to the customers.

2. Making Multiple Prototypes Fast

Aside from creating multiple molds, you can also use the rapid tooling equipment to create multiple prototypes fast. By creating multiple prototypes fast, you can create different versions of your prototypes and test different features of your prototypes. It will make it easier for you to decide which product design you would like to use in your final production process.

With rapid tooling, you don’t need to create prototypes one by one, which can take a lot of time to complete. Instead, you can prepare multiple designs of your prototypes and use the rapid tooling equipment to create those prototypes at the same time.

3. Time and Cost-Effectiveness in Manufacturing Production

As part of the rapid manufacturing process, rapid tooling can also help you produce all types of molds, prototypes, and products in much faster time. As a result, you can save a lot of time in your manufacturing production, making it easier for you to meet a tight production deadline. With the cheaper materials that you can use for rapid tooling, you can also save a lot of money in your production process.

Minimizing the time and costs required to produce prototypes, molds, and products in your manufacturing production means you can maximize the return on investment from each manufacturing production you perform.

4. Best for Material Testing

Using the rapid tooling method is also an excellent way for you to test different materials for your product. You can create multiple product samples or prototypes with different materials, whether they are plastics, metals, or any others. Then, you can test each product sample to see which material is the most suitable material for your product.

Conducting the material testing using rapid tooling will help you make decisions faster. Compared to traditional prototyping methods, rapid tooling will give you a significant speed boost in your production.

5. Quicker to Reach the Market

With rapid tooling, you can get your products ready for the market as soon as possible. You can speed up the testing process, and you can also speed up the production process for your products with this manufacturing method. The market will receive your products within your scheduled deadline, so you don’t need to worry about delays and various other production issues.

The quicker your products reach the market, the quicker it will be for you to rake up the profits from your production. Businesses need rapid tooling more because of the potential profits they can get by using this manufacturing method.

6. Flexible Prototype or Mold Design

You can use a wide range of prototype or mold designs with rapid prototyping, and the only limit is your creativity. With this manufacturing method, you can also adjust the prototype or mold designs as you see fit, depending on various factors, such as complexity, geometry, shapes, and so on. Each prototype or mold design can get modified later if you think that you need to add certain features or fix certain issues on the design.

Rapid tooling also supports complex geometry in your design, meaning that you can get your mold or prototype as feature-rich as possible. You don’t need to hold back in your design choice when it comes to using rapid tooling in your manufacturing production.

7. Faster to Execute New Design Ideas

Executing new design ideas is also something you can do with no hassles if you are using the rapid tooling method. Compared to the traditional tooling or prototyping method, you will be able to change your design choices for your prototypes or molds much faster and easier when you use rapid tooling.

In traditional tooling or prototyping, there will be plenty of steps you need to take just to change an aspect of your design. With rapid tooling, you don’t need to go through these complicated steps just to change an aspect of your design. Thus, it will be faster for you to execute new design ideas by using rapid tooling instead of using the traditional tooling or prototyping method.

Conclusion

With these benefits of rapid tooling, businesses can take advantage of this rapid manufacturing method to create prototypes, molds, and tools for their products to help them speed up their production process. Aside from that, rapid tooling is also useful to ensure that businesses can produce only the best quality products for their target market, so that they can have the highest customer satisfaction level possible for their products.

Rapid tooling will also help businesses to release as many products as possible to the market, with the minimal product manufacturing costs. This can help businesses ensure that their investments will return to them manifolds and they can get the highest profits possible from their business endeavors.